UZI Maintenance

|

UZI Maintenance |

Keep Your UZI Running

by

David Gaboury

The UZI is known as a tough, tireless workhorse that never

fails. While thereís a lot of truth to that, it needs good care like any other

firearm. Out of spec parts or poor maintenance can put your afternoon of fun on

hold quickly. Here are some suggestions to consider the next time your workhorse

stumbles. Most of these suggestions apply to fully automatic or semiautomatic

UZIs but youíll find that replacement parts for the semiautomatic are harder to

find and more expensive so thereís an incentive to repair rather than replace in

that case. The three most common problems youíll run into are failure to fire,

failure to eject and failure to feed.

Failure to Fire

|

| The UZI bolt face, showing unused firing pin (A) and the extractor claw (B) in the proper position. Note that the extractor rests on the raised rim just below the claw. |

A failure to fire occurs when the round is fed into the

chamber but the primer doesnít detonate. Usually the round will have a light

primer strike on it. There are three

possible causes for this. First, the open bolt firing pin, which is a small

projection milled into the bolt face, may be worn or broken. This is an uncommon

cause but if it happens, the firing pin will need to be welded up or the bolt

replaced. Surplus bolts are cheap and plentiful so replacement is usually the

easiest option. The firing pin on the semiautomatic UZI is pinned to the carrier

and can also be replaced if worn.

Another cause is excess headspace. If the round doesnít

seat firmly in the chamber, the bolt will push the round forward rather than

detonate the primer. Excess headspace can be caused by an out of spec chamber

but thatís uncommon. A more likely cause is a loose barrel nut. This simple to

diagnose, simple to fix problem can easily go unnoticed. With the barrel nut

tightened you should not feel any play in the barrel. If the problem is chronic,

it might be due to the barrel nut catch being worn or the teeth on the barrel

nut being broken off. Either part can be easily replaced. Remember to depress

the barrel nut catch when tightening the barrel nut to reduce wear on both

parts. If the problem persists, an easy cure is to put a rubber or copper gasket

between the barrel flange and the barrel nut. Another rare cause of excess

headspace is broken trunion welds. If the welds that hold the trunion inside the

receiver fail, the trunion will slide forward when firing the gun. Rewelding the

trunion should be done by a qualified gunsmith.

The final cause of failure to fire occurs when the bolt

moves forward so slowly that it doesnít hit the primer hard enough to detonate

it. This is actually a type of failure to feed and will be discussed later in

the article.

|

| Broken teeth on the barrel nut will allow the nut to loosen when the gun is fired. |

|

| If you can hear the clicks while tightening the barrel nut, then you are wearing out the front edge of the barrel nut catch. To avoid the problem, the barrel nut catch should be held down until the nut is tight. The catch on the left shows wear but the front edge is still square so itís serviceable. |

|

| The barrel trunion is welded to the receiver in two spots on each side. If the welds break, the trunion can slide forward as depicted in the right photo. The left photo shows the proper position of the trunion up against the front of the receiver. |

Failure to Eject

|

|

The point of the ejector (A) faces forward and strikes the base of the cartridge as the bolt recoils. The rivet head (B) can be seen to the side of the ejector. |

Failure to eject is also known as stovepiping. The first

possible cause of failure to eject is weak ammo. The heavy bolt and recoil

spring of an UZI require a heavier impulse to operate than a typical 9mm pistol.

UMC and Remington green box ammo are notoriously weak and can cause failures to

eject. If the empty cases are not ejected several feet from the gun, try

different ammo.

If ammo isnít the problem, take a look at the ejector. It

should be level, tight and pointing straight forward. Itís riveted to the bottom

of the receiver and if it gets loose it wonít firmly strike the back of the

fired case as the bolt recoils reward. To tighten a loose ejector, remove the

grip frame from the gun, exposing the bottom of the rivet. With the top cover

and bolt removed, turn the gun over and rest the head of the rivet on a support,

then hammer the bottom of the rivet until the ejector is tight. Once itís tight,

install the bolt without the recoil spring and push the bolt forward and

backward by hand. It should pass over the ejector without hitting it. Performing

this check with the barrel and stock removed will give you a better view of the

ejector clearance.

|

| To secure a loose ejector, turn the receiver upside down and support the rivet head. A bolt held in a vise makes a suitable support. Use a punch and hammer to peen the bottom of the rivet until the ejector is tight. |

If ejection problems persist, itís time to check the

extractor, which is the leading cause of failures to eject. The extractor must

firmly grip the case as the empty round strikes the ejector in order to generate

the energy needed to flip the case out of the gun. Remove and clean the

extractor, particularly under the claw. Residue buildup under the extractor claw

will prevent it from firmly gripping the case rim. Also clean the bolt hole that

the extractor sits in. A .22 caliber cleaning swab works nicely for this.

Residue in the hole will prevent the extractor from flexing properly. Before

reassembling, be sure that you have the correct extractor in the gun. 9mm

extractors are unmarked while the .45ACP extractors are stamped ď45Ē near the

back. They are not interchangeable. For best results itís also best not to mix

up semiautomatic and fully automatic extractors.

The lower point of the extractor claw is removed on the semiautomatic

extractor to facilitate feeding. When everything is clean, reassemble by

inserting the extractor through the back of the bolt. Line up the long slot on

the back of the ejector with the arrow on the back of the bolt. Reinsert the

extractor retaining pin from the left side of the bolt. Using a small

screwdriver, try to push the extractor claw sideways. It should require firm

pressure but move freely. If thereís no tension on it, the extractor will have

to be removed again and bent slightly. If nothing else seems to help, replace

the extractor.

|

| To remove the extractor, push the extractor retaining pin out and then push the extractor out from the front side of the bolt. |

|

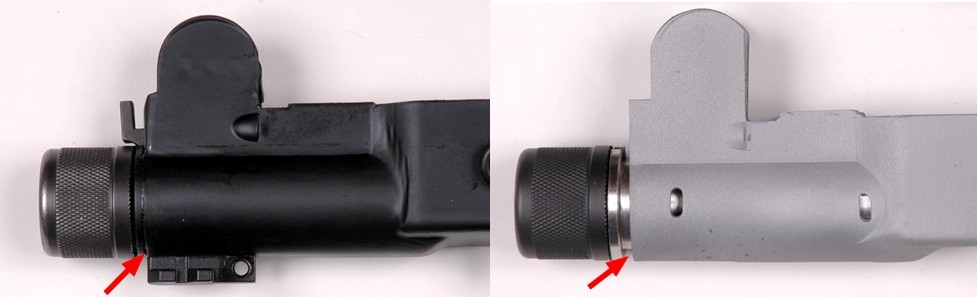

| The semiautomatic extractor (left) has one corner of the claw removed. This ensures reliable feeding as the case rim slides up the bolt face. Cases do not slide up the bolt face on fully automatic bolts because the lower lip of the bolt lifts the case rim over the extractor. The rim snaps under the extractor as the bolt closes. |

|

| The .45ACP extractor (top) is stamped ď45Ē. 9mm extractors are unmarked. |

Failure to Feed

Failure to feed is the most difficult problem to diagnose

because there are many potential causes. A failure to feed occurs when the bolt

cannot forcefully strip the round from the magazine and push it into the barrel

chamber. The problems fall into three categories: bad recoil spring, excess

friction on the bolt, or misalignment of the gunís components.

A weak recoil spring wonít impart enough energy on the bolt

for it to feed a round properly. Recoil springs can get weak with use and itís

good to have a spare on hand, but itís not a common problem. A more common cause

of a spring related failure is aftermarket springs that donít meet factory

specs. Surplus IMI springs are cheap and plentiful so you should replace it at

any sign of problems. The entire spring and recoil rod assembly should be

replaced as a single piece.

A much more common cause of failure to feed is excess

friction on the bolt and that can come from several sources. The first thing to

check is the gap between the bolt and the top cover. Use a feeler gauge

(available at automotive shops) to measure the gap. It should be between .005

inches and .015 inches; preferable about .010 inches. If the gap is too small,

the top cover will need to be bent to give more clearance. You donít need any

fancy equipment to bend a top cover; just a little patience and ordinary hand

tools. The easiest approach is to flip the top cover upside down and support

both ends with blocks of wood. Use a rubber mallet to hammer the middle of the

top cover to put a little bow in it. Do it slowly and re-measure the gap

frequently. If the gap is tight towards the front or back of the bolt, bend the

front or back of the top cover down. You can get by with a vise and a crescent

wrench to bend the ends of the top cover. Be sure the gap between the bolt and

top cover does not get excessively wide because it will allow the bolt to slide

past the sear without depressing the trigger. That would cause a ďrunawayĒ

condition and can be extremely dangerous.

|

| Insert a .005 inch feeler gauge between the bolt and top cover. If it does not move freely, the cover will need to be bent to reduce friction on the bolt. A .015 incher feeler gauge should be tight to avoid a runaway condition. Check the gap with the gauge inserted straight in, pointed backwards, and pointed forwards. |

|

| The long slot on the back of the extractor will be horizontal when properly reinserted in the back of the bolt. Fully automatic open bolts will have an arrow showing the proper alignment. |

If the top cover gap is okay, verify there are no other

sources of friction by using the bolt slide test. This test only works on open

bolt UZIs. Assemble the unloaded gun without the recoil spring, remove the

magazine, put the selector on full auto and hold down the grip safety. While

pulling the trigger, tip the gun forward then backward. You should hear the bolt

slide freely from the front to the back of the receiver. If itís binding

anywhere youíll need to find where itís rubbing and correct the problem. One

common cause of binding is trying to use surplus machine gun bolts in a

converted semiautomatic UZI that still has a barrel restrictor ring. An IMI

machine gun bolt will not have enough clearance and will rub on the top of the

restrictor ring. If thatís the problem, the best solution is to have a qualified

gunsmith cut off the top of the restrictor ring, leaving just the machined feed

ramp.

If friction isnít an issue, then the problem may be due to

misalignment of the gunís components. First check the magazine. Bent or cracked

feed lips will cause misfeeds so the easiest test is to try different magazines.

The original 25 round IMI magazines are the most reliable for function tests.

Another magazine related problem occurs if itís held too high in the

magazine-well. To test for this youíll need to repeat the bolt slide test

mentioned above, but do it with a magazine body inserted in the gun. You must

remove the magazine spring and follower for the test to work. If the bolt rubs

on the feed lips during this test, youíll need remove the magazine catch and

bend it so the magazine is held in a lower position. Check several magazines

before bending.

If the magazine alignment looks okay, the other potential

alignment problem is much more serious. When the barrel is not properly aligned

with the bolt, the round being fed into the chamber will not feed straight in,

resulting in a light primer strike or the round jamming between the bolt and

barrel. This type of alignment problem is most commonly found on guns built from

Group Industries receivers (original Group Industries or Vector guns) due to

those receivers being somewhat out of spec. Additionally, the heat treating done

by both Group Industries and Vector warp the receivers and they need to be

straightened before assembly, occasionally resulting in misalignment.

Straightening a misaligned receiver is not something you should attempt yourself

so if everything else checks out on your gun and youíre still experiencing

failures to feed, the best alternative is to contact Vector Arms for their

recommendation on factory repairs. Vector will do repair work on any brand of

UZI and their customer service is first rate.

Originally published in the

January, 2008 issue of Small Arms Review Magazine.

Copyright © 2002-2017, UZITalk.com

International copyright laws

DO apply to

Internet Web Sites!

All Rights Reserved.

Last Modified: May 27, 2017

Contact:

librarian@uzitalk.com