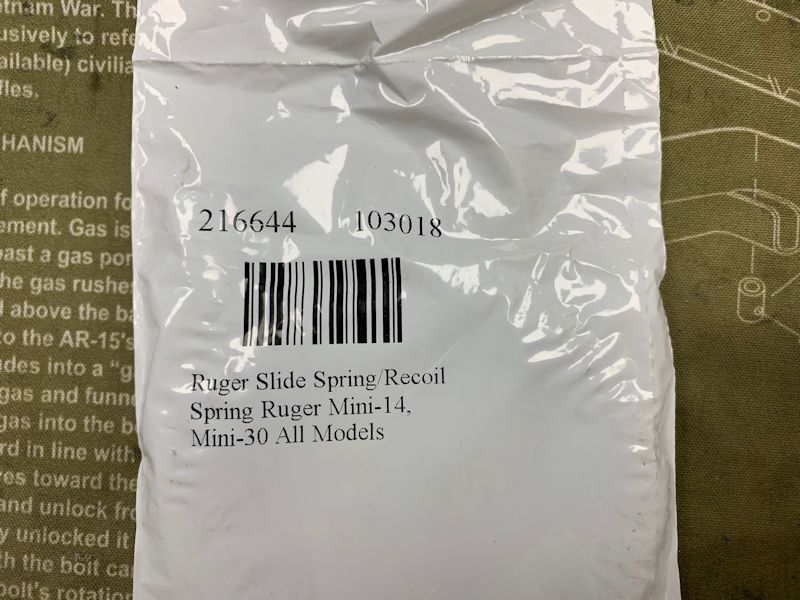

I have an AC556F that I've had for a couple of years. It was actually my first machine gun. I'd say that it's in very good to excellent condition and it runs 100%. About nine months ago I was fortunate enough to be able to purchase several machine guns from an estate as a package deal. Part of the package deal was another AC556F. It looks identical to my first. However, this one is in like new condition not having been fired since the former owner purchased it. When firing the newer one, I immediately noticed that the spent cases do not eject as far as they do from the other. I fired 100rds of Fiocchi 55gr FMJ 223Rem and 90rds of IMI 55gr FMJ 5.56x45 through it. There were multiple instances of the spent cases extracting, but getting caught by the action closing during the ejection process. My guess is that the bolt carrier isn't going back as far as it needs to or it's cycling too fast. I used my trigger pull gauge to estimate the amount of force required to cycle the action back to the point that the carrier encounters a second step of resistance. It took about a pound more force to cycle the new AC556F versus my first one, so that seems to indicate to me that it's not likely that the recoil spring needs to be replaced. Could it be some sort of issue of not getting enough gas? The piston seems to move just fine. I did notice that the four allen head screws on the front sight / gas block assembly don't seem to be screwed in the same amount. The forward ones seem to be screwed in more. I unscrewed them and found that one of the rear ones was very tight, while the others were pretty easy to unscrew. This is odd considering that the one that was tight didn't visually appear to be screwed in as much as the front ones. I don't know if this really means anything though. Is it possible that some gas may have been leaking out? I can soak all the parts and clean everything out.

Is there a torque specification for these allen head screws?

Is there a torque specification for these allen head screws?