hi uzitalk! I had problems with my printer when I moved it, she printed me beautiful ovals when I wanted a perfect round...all my printings being deformated! it took me time to repair and rebuild my firmware because I also forgot to add some important options.

my last modification on the size and profil of the dummies ammos make them move better inside the drum without blocking when they goes from the drum to the feeding tower. the first ones had not the right sizing and shape.

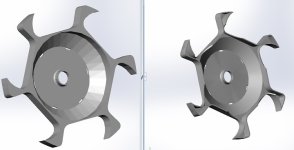

you can see the difference about size and shape, now I’ve got a little sanding to do!

i also made a new feed tower with a different internal shape but it was not necessary because the first one work.

my last modification on the size and profil of the dummies ammos make them move better inside the drum without blocking when they goes from the drum to the feeding tower. the first ones had not the right sizing and shape.

you can see the difference about size and shape, now I’ve got a little sanding to do!

i also made a new feed tower with a different internal shape but it was not necessary because the first one work.