Slotting an UZI Bolt

|

Slotting an UZI Bolt |

SLOTTING AN UZI

SMG BOLT

By Thor Vidar

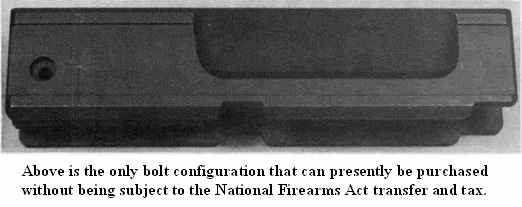

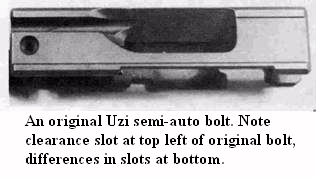

Once

readily available, the open firing Uzi bolt with clearance slot has been

declared a machine gun by the BATF. As a result, all known manufacturers of this

type of bolt have ceased production. The only way to get such a bolt, at this

time, is to purchase one of the open firing bolts which are slotless and alter

it yourself after BATF Form I approval.

Once

readily available, the open firing Uzi bolt with clearance slot has been

declared a machine gun by the BATF. As a result, all known manufacturers of this

type of bolt have ceased production. The only way to get such a bolt, at this

time, is to purchase one of the open firing bolts which are slotless and alter

it yourself after BATF Form I approval.

This is an interesting situation where the bolt is registered as a machine gun - not the weapon! A similar situation exists with the M2 Carbine conversion kit. The desirability of this type of conversion is the weapon itself being able to revert back to its original semi-auto status. The receiver isn't altered and the trigger mechanism of the Uzi can be made to function in the full auto mode by the addition of a special select lever known by such names as the "2-step".

The only open firing bolts now available are devoid of any clearance slot on the

side. Also, they function in the "full stroke:' manner. This means that the

large buffer block and semi-auto recoil spring must be replaced.

These

bolts have been hardened and to mill a slot in a normal machine shop operation

would require a ¼ inch diameter carbide ball end mill. These are both expensive

and easy to break. Hence, this formal operation is beyond the scope of the hobby

gunsmith and that brings us to the purpose of this article.

These

bolts have been hardened and to mill a slot in a normal machine shop operation

would require a ¼ inch diameter carbide ball end mill. These are both expensive

and easy to break. Hence, this formal operation is beyond the scope of the hobby

gunsmith and that brings us to the purpose of this article.

The open firing bolt can be slotted quite easily with tooling as simple as a table saw or even a power hand saw used in a table saw configuration. All that is required is to equip the saw with a set of two 7-inch diameter x 1/8 inch thick metal cut-off wheels. These wheels are made from aluminum oxide bonded into a reinforcement of resin and fiberglass. If the blade cover plate will not accept this extra thickness, a replacement plate can be placed on the saw and arbor and slowly raised, thus allowing the wheels to cut their own new opening. Another method is to replace the regular cover plate with one designed to be used with a DADO blade.

As with any

machine tool operation, proper eye protection should be used. A container of

water is necessary to cool the bolt during machining by submerging it after each

cut. Since you're using a woodworking saw, all the residue wood dust should be

removed to lessen the fire hazard.

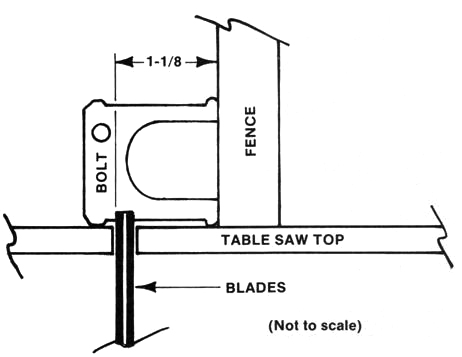

The

ripping fence is used as a guide and is initially set 1-1/8 inch from the

outside edge of the outermost blade. Since you'll be cutting on the underside or

"blind", some method of limiting the travel will be necessary. The easiest way

to accomplish this is to make a mark on either the table or fence with a crayon

or tape. A stop block could be "C" clamped to the fence if desired. This mark

should be located 2-5/16 inches from the center line of the arbor.

The

ripping fence is used as a guide and is initially set 1-1/8 inch from the

outside edge of the outermost blade. Since you'll be cutting on the underside or

"blind", some method of limiting the travel will be necessary. The easiest way

to accomplish this is to make a mark on either the table or fence with a crayon

or tape. A stop block could be "C" clamped to the fence if desired. This mark

should be located 2-5/16 inches from the center line of the arbor.

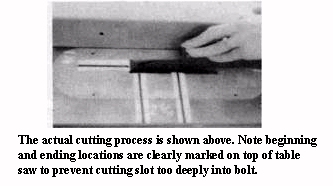

For the first cut, raise the cutting wheels 1/32 inch above the table. While holding the bolt firmly to the table and fence, slowly move it forward to the stop mark. Remove the bolt from the saw and immerse it in the cooling water. While the bolt is cooling, increase the height of the cutting wheels by 1/32 inch and repeat the previous step.

Repeat these 1/32 inch cuts until the slot is .380 inch deep. The resulting slot will have a small wedge of metal remaining in the center. This is a result of the double cutting wheel setup and can be cleaned up by removing one cutting wheel and repositioning the fence to place the remaining wheel in the center of the slot. Again, cutting in 1/32 inch increments, remove this wedge from the center of the slot.

The resulting bolt will have small corner radiuses at the bottom of the slot. If

a more professional job is desired, dress the outside edges of the double

cutting wheels to a 1/8 inch radius. The exposed metal in the slot can be

finished with cold blue. All that remains to be done now is to permanently mark

the bolt per BA TF requirements. This can be done with a carbide engraving tool

such as the Dremel Model 290. The marking should be located to be read in the

ejection port when the bolt is closed.

As

one last warning, please be advised that, by the preceding bolt alteration, a

machine gun (by legal definition) has been created, whether you possess the rest

of the gun or not. It is your responsibility to obtain BATF Form 1 approval

before the alteration begins.

As

one last warning, please be advised that, by the preceding bolt alteration, a

machine gun (by legal definition) has been created, whether you possess the rest

of the gun or not. It is your responsibility to obtain BATF Form 1 approval

before the alteration begins.

Originally published in the March, 1985 issue of Firepower Magazine.

Copyright © 2002-2017, UZITalk.com

International copyright laws

DO apply to

Internet Web Sites!

All Rights Reserved.

Last Modified: May 28, 2017

Contact:

librarian@uzitalk.com