History of the UZI

|

History of the UZI |

Officially created on May 15, 1948, the modern nation of Israel was immediately attacked by its Arab neighbors. Israel’s ill-equipped army defended itself with any weapons that were available. STEns, MP40s, Enfields and Mausers were widely employed. The lives of many Israeli soldiers were lost unnecessarily due to insufficient and non-standardized weapons. To rectify the situation, soon after securing a shaky cease fire, the Israelis sought to manufacture standardized weapons within their own borders. Instead of adopting a submachine gun with a proven design, such as a STEn or a Madsen M1946 (or M50), a new subgun, designed by Uziel Gal, was chosen. Though Uziel Gal’s submachine gun was new, there was nothing original in its design. To quickly arm his new nation, Gal copied the innovative features of two modern Czechoslovakian subguns, the ZK 476 and M23/25.

The First Example of A Third Generation Subgun

Designed by Josef and Frantisek Koucky, the Czechoslovakian The ZK 476 represents an historic marker in submachine gun development. It was the first subgun to incorporate every feature that defines a classic third generation subgun. (For a detailed description of the generations of subguns, see Small Arms Review Volume 2, Number 1. Back issues are available from Moose Lake Publishing.)

Second and third generation subguns share one basic design characteristic. Both generations were designed for quick and inexpensive production. Low cost production methods are the first characteristic of a third generation subgun. The ZK 476 combined the second generation’s simplified manufacturing techniques with two new design innovations and created another class of subgun….The third generation.

The Telescoping Bolt

The Telescoping Bolt

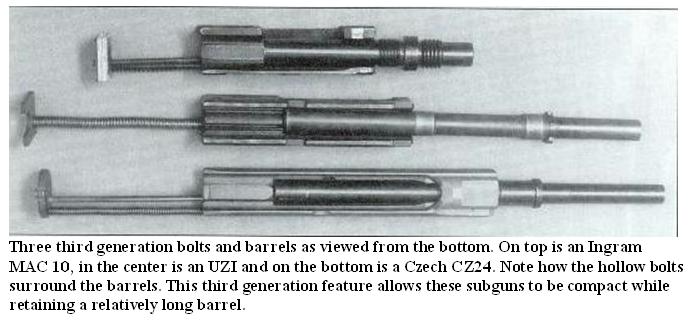

The first major innovation of the Czech ZK 476 was its use of a telescoping bolt. Not original to the ZK 476, this type of bolt was first used on an earlier Koucky subgun, the ZK 467. Firing from a closed bolt and looking much like a carbine or a Beretta M38a subgun, the ZK 467’s hollow ‘telescoping’ bolt partially surrounded the barrel when closed. This advanced bolt design allowed a shorter overall length.

The Koucky telescoping bolt adds another level of safety. At the moment of ignition, the hollow bolt places a thick metal shield between the cartridge and the shooter’s face. In view of the dubious quality of some imported 9mm ammo, this is an important consideration.

The Kouckys may not have invented the ZK 467’s ‘telescoping’ bolt though. Some

authorities believe that Vaclav Holek, another Czech designer, invented it

during the WW II German occupation of Czechoslovakia. Another report states

that as early as 1945, the British were experimenting with a telescoping bolt

subgun. Neither claim for a telescoping bolt that preceded the ZK 467’s can be

verified. No examples exist to support these claims. The Koucky ZK 467 is the

first confirmed example of a subgun to use this new, innovative type of bolt.

The Second Innovation of a Third Generation Subgun

The Second Innovation of a Third Generation Subgun

Though in the 1930’s a few Colt 1911 pistols were converted to full auto, the Koucky ZK 476 was the first true subgun to have a centrally located pistol grip containing a magazine well. The magazine-well-in-pistol-grip is the second defining characteristic of a third generation subgun. This feature makes reloading much easier, especially at night. “Hand finds hand,” is a natural ability.

Having a centrally located pistol grip has a second benefit. The ZK 476, the UZI and all well designed third generation subguns are well balanced. Emergency one-handed firing is less difficult with a well-balanced third generation subgun.

The combination of a ‘telescoping’ bolt and a ‘magazine-in-the-pistol-grip’ was the breakthrough that allowed the Koucky ZK 476 to be very compact while retaining its eight inch barrel. Much copied by others, the ZK 476’s simplified construction methods, its ‘magazine-in-the-pistol-grip’ and its ‘telescoping’ bolt make it, unquestionably, the first example of a third generation subgun.

A bit of trivia here from THE WORLD’S SUBMACHINE GUNS. ”…. the first subgun to balance at its pistol grip was not the ZK 476, it was the 1941 Australian Owen.” Technically, this broad claim is not quite correct. Though heavy, a Thompson subgun with a twenty round (XX) magazine does balance at its pistol grip. With a “D” or “C” drum magazine however, it does not.

Unlike the ZK 476, the Australian Owen was not a third generation subgun. Neither was it a second generation. Made with much skilled labor and machine tool time, like a Thompson, the Owen was a first generation subgun.

Like a second generation subgun’s, the Owen’s receiver was made from extruded steel tubing. Nearly every other part however, was made on a milling machine from a solid bar of steel. This required the labor of a skilled craftsman. Even the Owen’s extruded tubing receiver was labor intensive to complete. The magazine well and the release pin housing for the quick-detachable barrel were welded to the receiver. The welds were then polished so smoothly that the mag well and release pin housing appear be seamless parts of the receiver.

Only the Owen’s lack of wooden furniture made it appear to be a second

generation subgun. Later model Owens did have wood inserts in their steel

stocks. The Owen’s pistol grip has no magazine well of course, but it is

centrally located at the subgun’s point of balance.

More Shared Features

More Shared Features

Koucky ZK 476s and UZIs have ambidextrous cocking knobs on top of their receivers and grip safeties. Both fire from an unlocked, open bolt. Both UZIs and ZK 476s have advanced ignition. This feature has the effect of ‘softening the recoil and enhancing controllability while allowing the subgun to weigh less. In full auto, an UZI will consistently shoot smaller two and three-shot groups than will a closed bolt H&K MP5. To approach the controllability of an UZI, an MP5 must have an efficient muzzle brake or suppressor.

Advanced Ignition 101

The advanced ignition principle is quite simple. It requires no extra parts. An advanced ignition open bolt subgun’s chamber depth is made a few thousands of an inch shorter than the cartridge case’s length. This causes the forward moving bolt’s fixed firing pin to ignite the primer a moment before the bolt strikes the chamber face. As the recoiling cartridge case begins pushing rearward, it meets the resistance of the forward-moving bolt. The two forces oppose each other. The bolt’s motion is reversed and the cartridge’s felt recoil is reduced. The use of advanced ignition makes the firing cycle seem smoother to the operator.

Advanced ignition also enhances controllability by reducing the subgun’s muzzle ‘climb.’ The heavy telescoping bolt’s center of mass is moving forward of the subgun’s center of gravity (CG) at the point of cartridge ignition. The inertial action of the telescoping bolt, pushes the advanced ignition subgun’s muzzle forward and down, thereby reducing felt recoil and countering the recoiling cartridge’s attempt to make the muzzle ‘climb.’ If the subgun designer has done his job well, the two opposing forces cancel each other and the subgun is very easy to control in full auto.

Finally, the inertia of an advanced ignition subgun’s forward moving bolt must be overcome by the recoiling cartridge case. This allows the weight of the bolt to be reduced, decreasing the subgun’s weight.

The First Subgun With a Grip Safety

The First Subgun With a Grip Safety

The Koucky ZK 476 has a shooting-hand activated grip safety. It may be the first of its kind on a subgun (disregarding the full auto converted 1911 Colt pistols. This is not certain however. The French M.A.S. C1 subgun also has a shooting-hand activated grip safety. Both the French C1 and Czech ZK 476 were developed during the same time period.

To be technically correct, it must be mentioned that the 1945 Italian TZ-45 was the first subgun to have a grip safety. The TZ-45’s grip safety is activated by the non-shooting hand though. It is very similar to the grip safeties of the more familiar Madsen M1946 and M50. (See “The Madsen M50” in Small Arms Review Volume 2,Number 2)

Czech Models 23 & 25

Manufacturing records are incomplete, but it appears that only a few Czech ZK 476s were made. Only two examples are known to exist today. The first subguns of the third generation to be manufactured in significant quantities were the Czech Models 23 and 25. Resembling the soon-to-be-produced UZI, both models were identical, except that the Model 23 had a fixed wood stock and the Model 25 had a folding metal stock. Unlike the preceding ZK 476 or the UZI that followed it, the Czech models 23 and 25 lacked a grip safety.

Said to have been designed by Vaclav Holek, production of Model 23 and 25 subguns began in 1949 at the Ceskoslovenska Zbronka (CZ) factory in Uhersky Brod. Over 100,000 of the two models were manufactured before their production ended in 1952, just as UZI production was beginning.

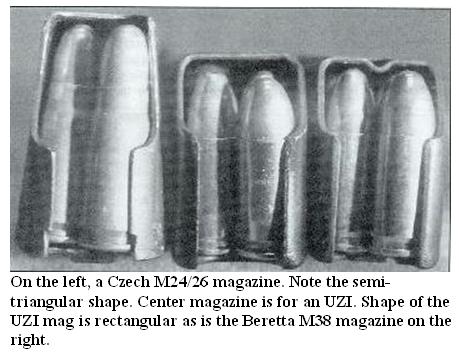

The Model 23/25’s magazine was original. Though its double-column, two-position feed method had been used previously, Holek’s Model 23/25 subgun was the first to have a magazine with a semi-triangular (wedge) plan form. Instead of two parallel columns of ammo, the M23/25’s semi-triangular magazine angled the cartridges toward the center. This enhanced feeding reliability. Soon after the M23/25 was introduced, a very similar 36 round magazine for the Swedish K appeared.

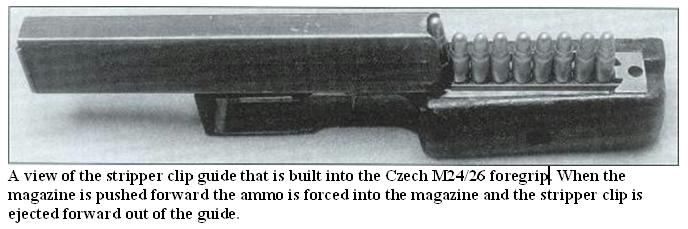

The CZ 23/25 had one useful feature that Uziel Gal chose to ignore. A stripper clip guide was attached to the right side of the subgun’s fore grip. A 32 round magazine could be filled in seconds using stripper clips and the built-in guide.

To avoid

confusion, the CZ models 24 and 26 must be mentioned. Models 23 and 25 Czech subguns were chambered for 9X19mm ammo. Models 24 and 26 were chambered for the

more powerful Russian 7.62X25mm round. Like the Models 23 and 25, the only

difference between the Models 24 and 26 were their fixed wood and metal folding

stocks.

Gal’s Simplifications

Though Uziel Gal originated no new innovations when he designed the subgun that bears his name, his design did simplify the manufacturing process. The receivers of Czech Models 23 and 25 are made from extruded tubing. Though the tube is simple to make, precise machine work is required to cut the required holes for the magazine well, the ejection port and the slots for the cocking knob and the sear.

UZI receivers are simpler, cheaper and faster to manufacture. Like Danish Madsen M50s and STEn MKIIIs, UZI receivers are stamped from flat metal sheets, much like using a cookie cutter to cut cookies from dough. In one step, the UZI stamping dies cut out the receiver and make every required hole. This eliminates time consuming, costly machine work. In the final step of the receiver forming operation, the flat stamped receiver sheets are bent around forming dies. This gives them their rectangular shape.

Making the stamping and forming dies and then setting up the machinery to manufacture Gal’s subgun was costly and time consuming. Once the production line was in place though, UZI subguns could be produced rapidly and inexpensively.

Gal also simplified the M23/25’s ejector. An UZI’s ejector is just a simple ‘post.’ It is riveted to the receiver. The M23/25’s ejector is a short rod that is attached to the buffer pad support. Adjacent to the ejector rod is the operating spring guide rod. It is attached to the buffer pad support too. There is a tube-like hole in the M23/25’s bolt. The M23/25’s ejector rod passes through it.

Though not copied by Gal, the M23/25’s excellent ejector did not go unnoticed. Gordon Ingram adopted it for his MAC10 and M11 designs.

Born of Necessity

The Israeli UZI and the British STEn were both born of dire necessity during troubled times. (For more details, read “Britain’s Salvation” in Small Arms Review, Volume 1, Number 3) When these subguns were developed, each nation feared that an invasion was eminent. Both nations needed to arm quickly. The urgency necessitated developing a subgun that could be produced quickly and cheaply. Both nations succeeded admirably and created classic subguns. The STEn however, was replaced with a better subgun only eleven years after its birth. Due to its superior qualities, the UZI, unlike the STEn, is still going strong after fifty years.

Made of inexpensive stampings like a STEn MKIII, UZIs, in addition to their compactness, exhibit a quality in their design and manufacturing that STEns lack. One example of the UZI’s quality is its superior adjustable sights. Another example is the long ridges that are stamped in the sides of the UZI’s receiver. Simple to make, their importance is often overlooked. These ridges both strengthen the receiver and serve as efficient traps where fouling can accumulate harmlessly between cleanings. This helps to ensure reliability in harsh combat conditions.

The first UZIs had wood stocks and either wood or fiber pistol grips and fore ends. Plastic grips and fore ends soon appeared. The earlier wood stocks were two inches longer that the later wood stocks. The folding steel stock, which is almost an UZI trademark today, did not appear until 1960. Folding stock UZIs were first issued, not to Israeli soldiers, but to the West German 'BundesgrenshutzGrupen' (Border Patrol), who were the first foreign nationals to adopt the UZI.

The UZI’s folding metal stock is, arguably, the best folding or retracting stock of any subgun. Due to its central pistol-grip-magazine-well, telescoping bolt and folding stock, the UZI is very compact. When the stock is folded, its length is only 17.5 inches.

The concept of a folding or retracting stock, however, was not new in 1960. Hugo Schmeisser applied for a patent on one in 1935. Schmeisser’s retracting stock was not the first of its kind either. In his patent application, he stated that folding and retracting stocks were already known and that his application was for an ‘improved’ retracting stock.

Safety/Fire Control Selector

Safety/Fire Control Selector

An UZI has two safeties. The first is the previously discussed grip safety. The grip safety is automatically engaged if it is not deliberately squeezed. The grip safety prevents an accidental discharge by locking the bolt in either the forward (at rest) or rear (cocked) position.

The grip safety must be squeezed to either cock or to fire an UZI. If loaded, many second generation subguns will fire if they are dropped on their butts. Due to its grip safety, an UZI will not.

A manual safety is incorporated into the UZI’s fire control selector. The aft position is SAFE. When the manual safety is engaged, even if the grip safety is squeezed, the bolt cannot be retracted. Additionally, when the selector is moved to SAFE, a bar moves rearward, under the sear, preventing the user from pulling the trigger.

Moving the UZI’s selector forward, to the middle position, selects SEMI AUTO and permits the user to cock the subgun if the grip safety is squeezed. The UZI’s method of achieving semi auto fire is quite advanced. Many less advanced subguns achieve semi auto fire by moving a ‘tripping lever’ upward into the path of the bolt. When the trigger is pulled and the bolt moves forward, the bolt strikes the ‘tripping lever,’ forcing the ‘tripping lever’ downward. The downward moving ‘tripping lever’ pivots on a central pin and its rear portion moves upward lifting the sear. After the subgun fires one round, the bolt retracts past the sear. When the operating spring pushes the bolt forward again, the bolt is caught on the uplifted sear.

As long as all of the working parts are in order, the ‘tripping lever’ method of achieving semi auto fire works fine. Unfortunately, the temper of the ‘tripping lever’ is critical. If it is too soft, it will soon wear out and the subgun will fire full auto when semi is selected. If it is too hard, the ‘tripping lever’ may be brittle and break. Fortunately, if the ‘tripping lever’ breaks, the subgun’s full auto function is usually unimpaired after the broken portion is removed. The soldier may only be able to fire in full auto, but he will not be without a weapon until it can be repaired properly.

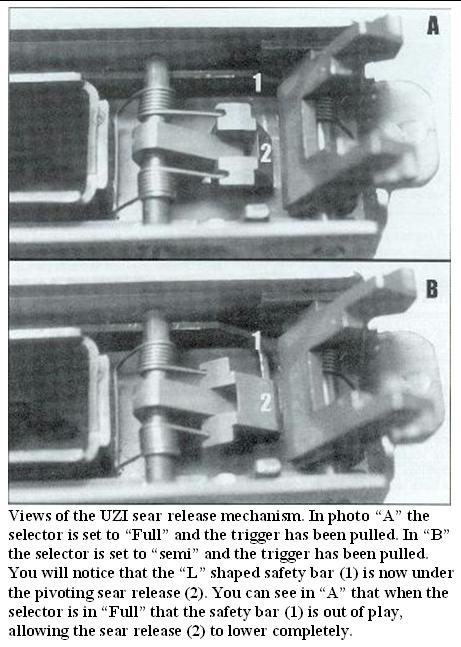

Instead of the using the ‘tripping lever’ method to attain semi auto fire, when set to SEMI AUTO, an UZI’s safety bar moves under the pivoting sear release mechanism. When the trigger is pulled, the sear mechanism pivots on the safety bar. A moment after the sear releases the bolt, the pivoting semi auto mechanism releases the sear. The spring-loaded sear pops up quickly to stop the bolt after firing one round.

The UZI’s most forward selector position is FULL AUTO. In this position, the safety bar is completely ‘out of play.’ The trigger pulls the sear out of engagement with the bolt and the UZI will fire automatically until either the trigger is released or the ammo is exhausted.

Safety Enhancing Improvements

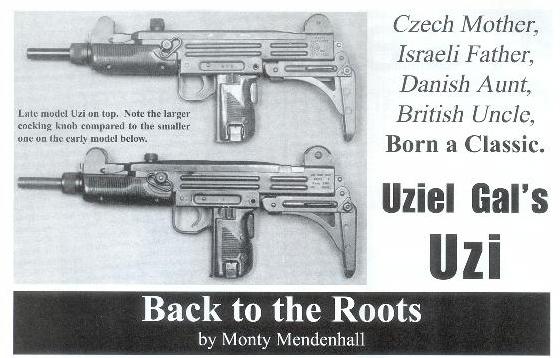

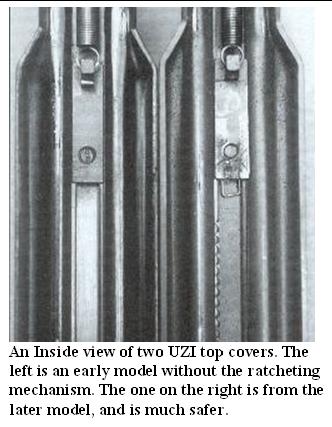

Two UZI improvements, adopted about 1960, made it even safer. Recall that an UZI’s manual safety must be set to either SEMI or FULL AUTO and its grip safety squeezed before an UZI can be cocked. In this condition, an UZI is ready to fire. If the shooter’s hand slips off of the cocking knob while cocking, the bolt can move forward, strip a round from the magazine and fire. To help prevent accidents of this type, the UZI’s cocking knob was enlarged. The larger knob provides a surer grasp to help prevent the shooter’s hand from slipping.

A ratchet mechanism was also added to the enlarged UZI cocking knob. If the shooter’s hand does slip off of the ratcheting cocking knob while cocking, the ratchet will catch the bolt and prevent an accidental discharge (AD). These two innovations are completely contained within the easily removable top-cover. Retrofitting an early model UZI to the new, safer configuration only requires exchanging top-covers. Upgrade time? Ten seconds.

UZI Magazines

UZI Magazines

Instead copying the Czech 23/25’s new triangular magazine, Uziel Gal chose to use a proven Beretta two-column, two-position feed subgun magazine. The Beretta magazine has an interesting history. It is a direct descendant of the magazine that was used on the first pistol caliber machine gun, the Villar Perosa. For more details about this historic magazine read “The Beretta M38” in Small Arms Review, Volume 3, Number 11.

Genuine IMI UZI 9mm magazines are available in four capacities, 20, 25, 32 and 40 rounds. Some RKIs have stated that UZI 40 round magazines and Beretta 40 round magazines, upon which the UZI magazine is patterned, are unreliable. The author has had no experience with original IMI 40 round UZI magazines. He does have experience though with original Beretta 40 round magazines. In his experience, they have been flawless in a Beretta M38a. At the Spring 2001 Knob Creek Classic Subgun Match, first and second places were won by a wide margin by competitors who were shooting a Beretta M38a and using 40 round magazines.

Accessories

Accessories

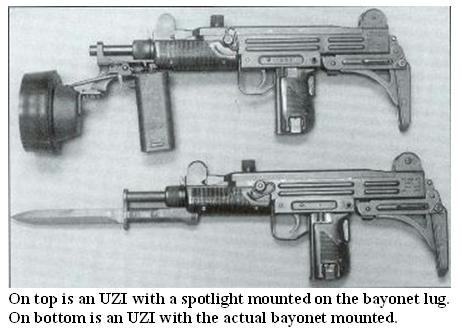

An UZI Subgun can mount a bayonet. Some ask, “Why?” There actually may be a legitimate use for one, …controlling crowds or herding prisoners.

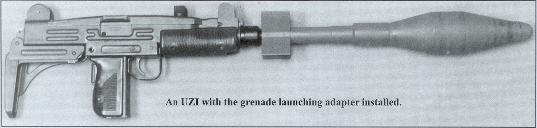

Perhaps of more practical value though, is a grenade launching fixture that replaces the UZI’s barrel locking nut. Launched by a special grenade launching blank cartridge, an UZI anti-tank grenade is said to be capable of penetrating seven inches of steel armor.

A bright spotlight can be attached to the UZI’s bayonet mount. Its slim battery compartment serves as a forward pistol grip for the non-shooting hand. A trigger-like switch is located on the fore grip. It activates the spotlight. The switch is spring loaded to the OFF position.

IMI makes magazine brackets that allow two UZI magazines to be connected at a ninety degree angle. Their purpose is to assist in making quick magazine changes. The author finds them to be awkward to use but other RKIs like them. The weight of the forward protruding magazine is said to help control the UZI’s already minimal muzzle ‘climb.’

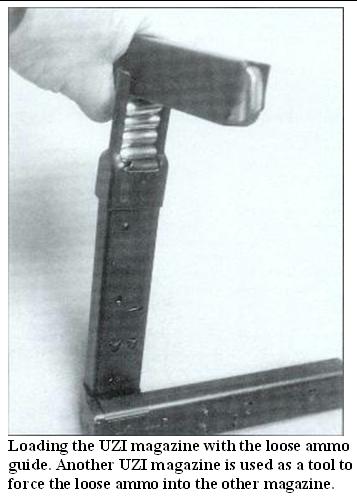

UZI double column, double feed magazines are easy to load. No loading tool is necessary. Though unneeded, IMI does sell a combination UZI magazine loading and unloading tool. The magazine loading tool is a cartridge guide that fits the top of the magazine. No stripper clips are used with the tool. Five rounds of loose ammo are stacked vertically into the guide and another UZI magazine is then used to press them into the empty magazine.

At the base of the loading tool is an ‘unloading finger.’ To use it, hold the loaded UZI magazine parallel to the ground with the bullet pointing downward (primer up). Place the ‘finger’ on the second cartridge and compress the magazine spring until the base of the tool contacts the left and right magazine lips. At this point, the top cartridge will fall from the magazine. While holding the tool firmly against the magazine lips, move it swiftly from side to side. The rest of the cartridges will fall out.

Though tedious to describe, using the UZI magazine unloading tool is simple. Many people, however, still prefer to unload an UZI magazine the old fashioned way, ... with the trigger.

More compact than most previous subguns, in 2001, UZIs are available in .22LR, .40AE, 9mm and .45acp. Several countries have produced copies of Uziel Gal’s ubiquitous subgun. These include China (Norinco), Belgium (FN), U.S.A. (Group Industries and Vector Arms), Cuba, and France. The Israeli IMI and Belgian FN UZIs are generally believed to be the best of made of them all.

Uziel Gal’s Opus Magnum

In 1963, Thomas Nelson stated, “(The UZI is)…a submachine gun which, in design and function, leaves little to be desired. …It is now the most widely distributed submachine gun in the Western World. (THE WORLD’S SUBMACHINE GUNS, Volume 1)

The UZI submachine gun recently celebrated its fiftieth birthday and it is still is production. The UZIs that are produced today differ only in minor details from those made in 1951. Though his subgun contained nothing that was original, Uziel Gal copied and simplified the best features of modern subgun designs to quickly arm his emerging nation. While doing so, he created a classic. Before World War Two, when most people thought of a submachine gun, they visualized a Thompson. Most people born in the sixties visualize an UZI.

Originally published in the January, 2002 issue of Small Arms Review Magazine.

Copyright © 2002-2017, UZITalk.com

International copyright laws

DO apply to

Internet Web Sites!

All Rights Reserved.

Last Modified: May 28, 2017

Contact:

librarian@uzitalk.com