About a week ago I made a 1200 round trip to go pick up this little guy and satify my MTAD (Machine Tool Acquisition Disorder). Poor old mini truck worked for a living and hills were not my friend. Really need to get MPFI converted and find a supercharger but thats a different project.

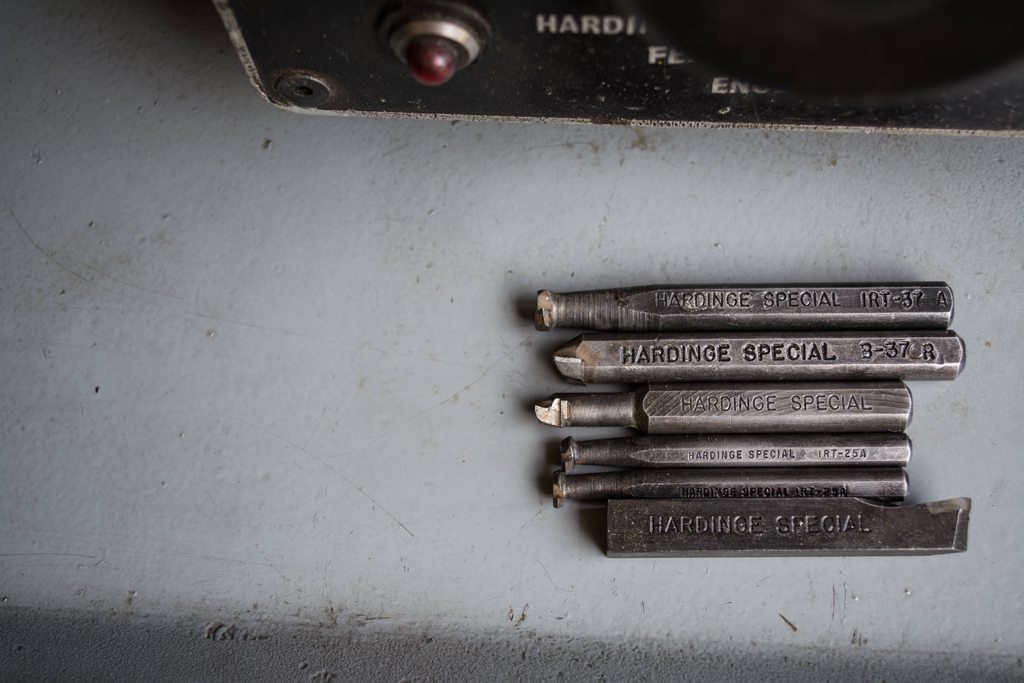

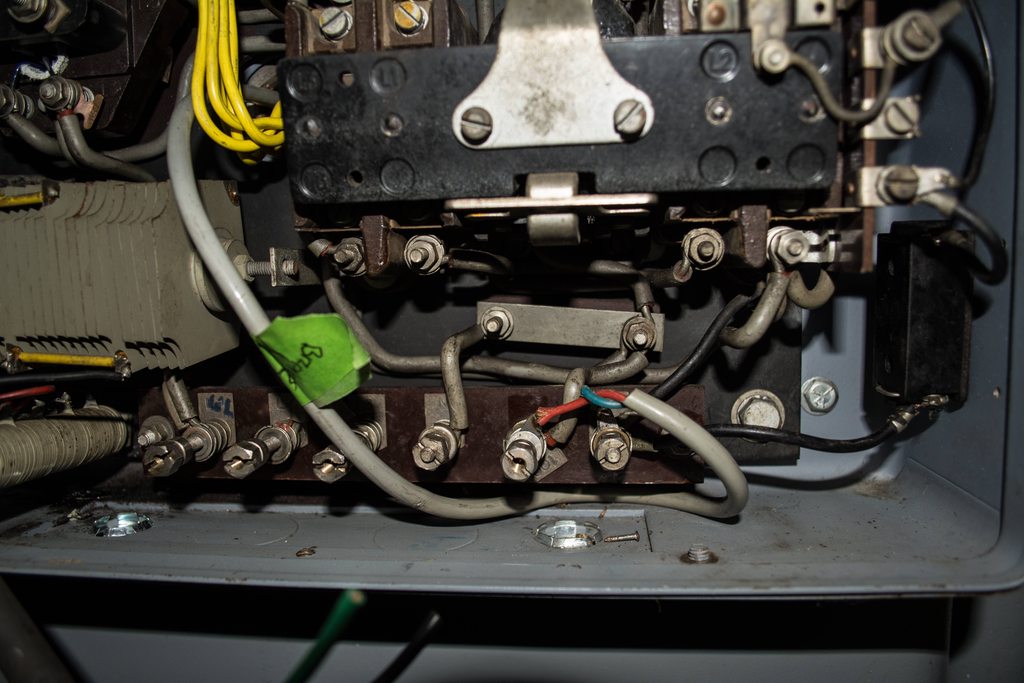

The lathe is a 1947 Hardinge HLV with a 0027 serial number. Its pretty early. I still have some work before I can turn it on. It was completely restored which meant everything came off so I get to finish up some control cabinet wiring. I was told it has an issue with the power feed motor, likely the selenium rectifier. Need power to check that. Got the aloris toolpost mounted today. Need to find some good photos of the identification plaques so I can make new ones. Plan to laser engrave anodized aluminum.

To get power to it I need to extend the run from my phase converter and add a disconnect. Then see if I get to wire in a modern diode rectifier or replace a variac or replace a motor.

Anyways, pics. Enjoy!

The lathe is a 1947 Hardinge HLV with a 0027 serial number. Its pretty early. I still have some work before I can turn it on. It was completely restored which meant everything came off so I get to finish up some control cabinet wiring. I was told it has an issue with the power feed motor, likely the selenium rectifier. Need power to check that. Got the aloris toolpost mounted today. Need to find some good photos of the identification plaques so I can make new ones. Plan to laser engrave anodized aluminum.

To get power to it I need to extend the run from my phase converter and add a disconnect. Then see if I get to wire in a modern diode rectifier or replace a variac or replace a motor.

Anyways, pics. Enjoy!